How canned tuna is processed, step by step

Manual elaboration of canned tuna is a long-standing tradition in the Basque Country, particularly in cans that weigh more than one kilo, directed to the catering sector. While small cans that are widely consumed in households are packed by machine; big cans contain full pieces of tuna that are introduced by hand. This is the case of the 1800 gr. can, which is produced following these steps:

Step 1: Reception and cutting

We receive the pieces of White Tuna and Yellowfin Tuna at our facilities. In the case of White Tuna (Bonito del Norte) the fishery starts on June and it lasts until September or October, period in which fresh fish is used for the elaboration of cans, guaranteeing the best taste and texture of the tuna. Moreover, our production plant is strategically located in Bermeo, a coastal village in the Bay of Biscay, where the white tuna is fished. This ensures maximum freshness and quality of the tuna.

After receiving the fish, the head and the belly are removed. Then we cut every piece of tuna into sections.

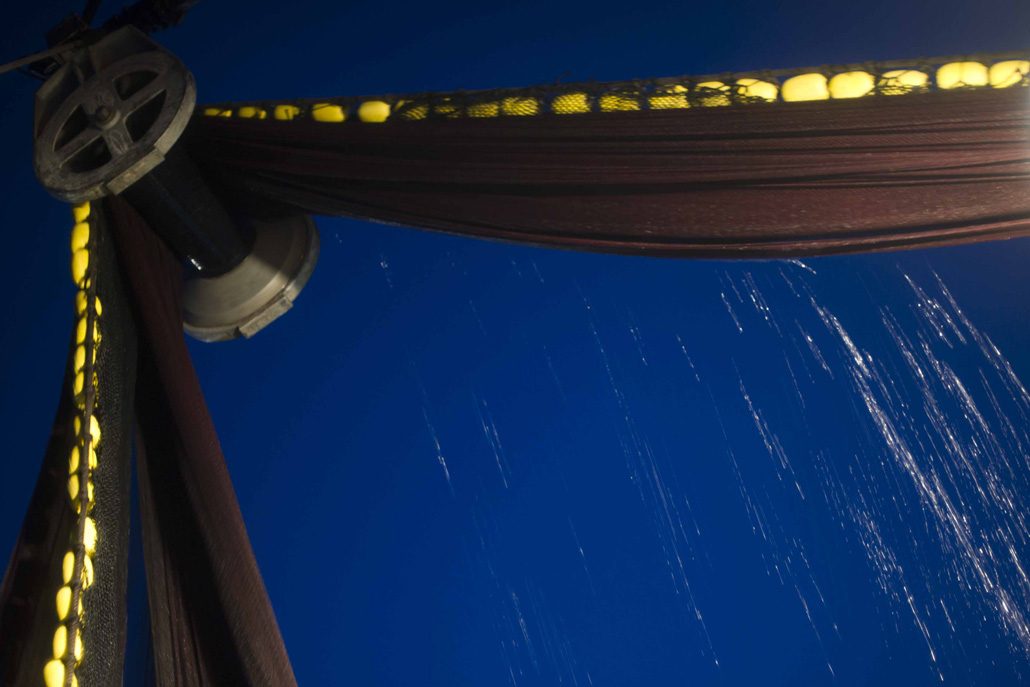

Step 2: Cooking

The slices of tuna are introduced in big containers for the cooking. We add the perfect mix of water and brine and calculate the time it takes each fish to cook. After this process, tuna pieces look like this :

Step 3: Manual packaging

We clean all the slices of tuna by removing the skin, bones, fins, and any remaining entrails or dark meat. Then we introduce manually the pieces into the can.

Step 4: Adding liquid and closing

The covering liquid is prepared and added. In our case, it may be olive oil, sunflower oil, pickled sauce, catalan sauce or water. After this, cans are closed and sterilized. The sterilization process ensures the destruction of all contaminating bacteria, so the product is fit for human consumption.